Laser Marking Additives

Permanent, Precise, Sustainable.

Laser marking on plastic components delivers permanent, abrasion-resistant

identification without the limitations of traditional methods. Unlike ink-based printing, it’s an environmentally responsible solution—eliminating

solvent-based inks and generating zero waste.

For most thermoplastics, Near-Infrared (NIR) laser marking requires a specialized

additive that enhances the interaction between the laser and the polymer. This ensures sharp, high-contrast, and durable marks, even on challenging

substrates.

Why choose laser marking?

- Permanent and tamper-resistant identification

- Eco-friendly process with no inks

- High precision for technical and decorative applications

- Versatile for flat, curved, and 3D surfaces

Applications across industries

Laser marking technology is widely used for traceability, branding, and personalization in multiple sectors:

- Animal identification

- Automotive components

- Decorative & branding

- Packaging solutions

- Personalization

IRASORB laser marking range

At Keeling & Walker, we manufacture the IRASORB range of laser marking additives, designed to deliver exceptional performance across a wide variety of polymer formulations. These

additives enable consistent, high-quality results, meeting the demands of modern manufacturing for precision, durability, and sustainability.

| Product | Advantage |

|---|---|

| Irasorb LM002 | All polymers up to 280 degrees Celsius |

| Irasorb LM005 | High thermal stability, all polymers processed above 280 degrees Celsius |

| Irasorb LM008 | All polymers up to 280 degrees Celsius, exceptional contrast |

| Irasorb BITO | Transparent polymers |

| Stanostat CPM10F | Universal additive for all light/white marks |

Marking Transparent Polymers

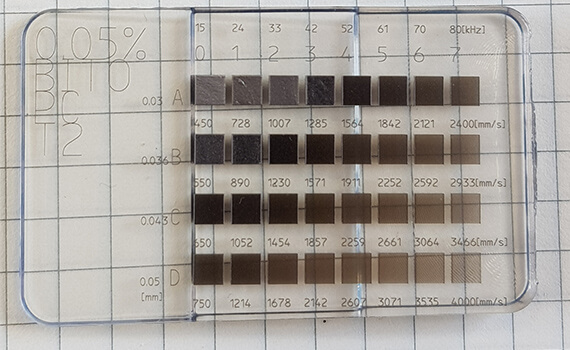

Laser marking of transparent polymers requires nanoscale sized additives in order to retain the optical transparency. Only well dispersed nanoscale additives provide the high degree of transparency and laser sensitivity required to generate good marking results. Irasorb BITO is the preferred solution for this challenging application.

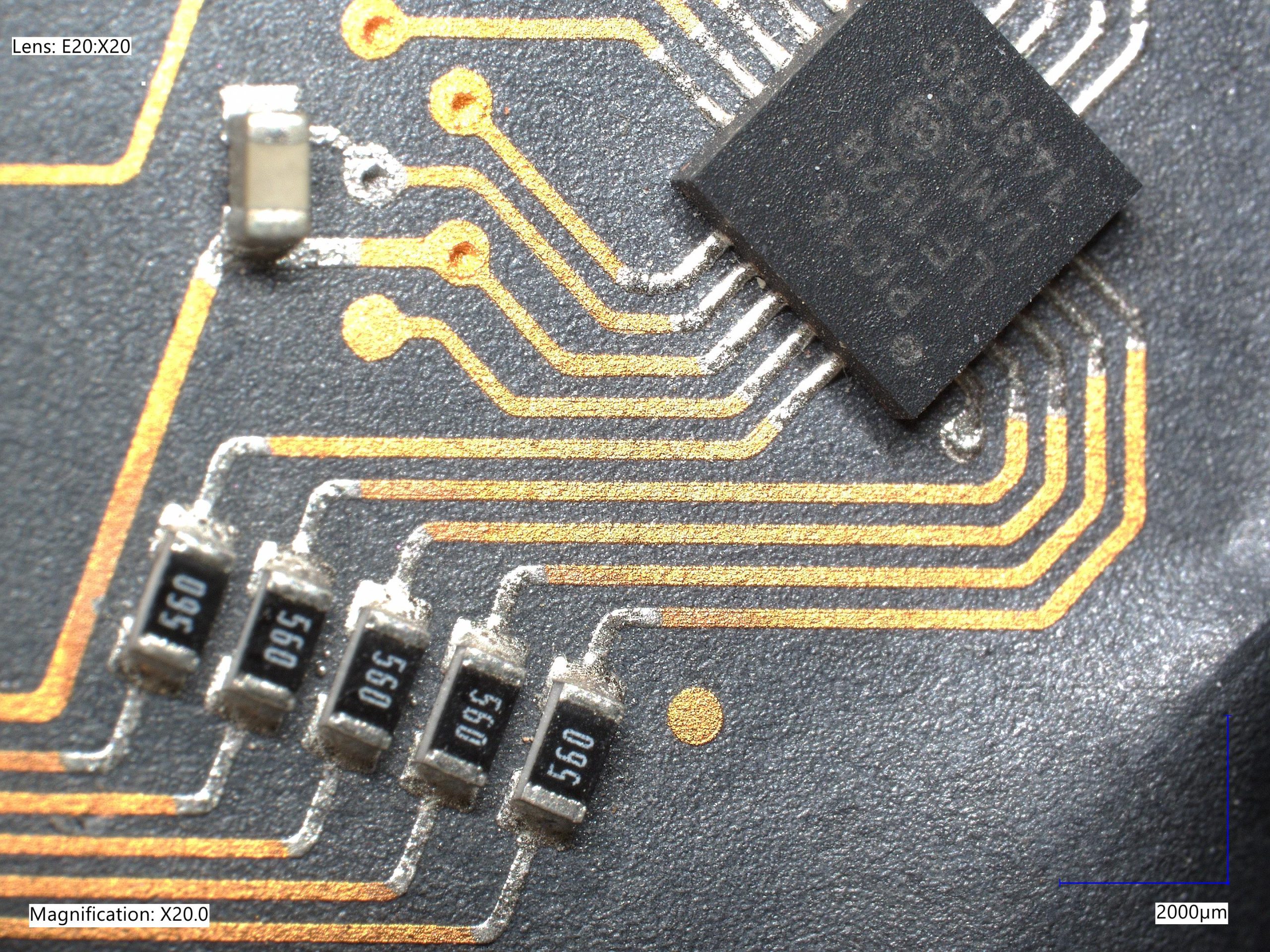

Laser Direct Structuring (LDS)

The Laser Direct Structuring (LDS) process revolutionizes electronic design by enabling circuits to be created directly on 3D polymer or ceramic components—eliminating the need for traditional printed circuit boards. This approach allows high component density and miniaturization, making it ideal for modern, compact devices.

How It Works

Our LDS additives are incorporated into the polymer during injection moulding. After moulding:

- A laser selectively activates the surface

- The part undergoes metallization, where metal deposits only on the laser-marked areas.

- Electronic components are then mounted onto the structured surface.

This process combines design flexibility with precision manufacturing, enabling complex circuits on curved or irregular shapes.

| Product | Advantage |

|---|---|

| Irasorb LM005 | Multipurpose- light coloured LDS additive and laser marking additive |

| StanoStat CP5C | Dark grey LDS additive |

| StanoStat CP05 | Dark blue LDS additive with high plating activity |

| CCTO | Brown powder, Sb-free LDS additive |

Challenge Us

At Keeling & Walker, we work closely with customers to deliver tailored laser marking solutions. Our team provides specialist polymer marking consultancy, backed by in-house laser systems for testing and small-scale trials. Whether you need technical guidance, test batches, or help with complex applications, we’re here to ensure optimal marking performance. For challenging projects, we collaborate to develop innovative solutions together.

Exciting News!

We are thrilled to announce that our brand-new Research and Development Building is well

Our products are manufactured to the ISO 9001 Quality Assurance Standard. Learn about Keeling and Walker's commitment to quality.

We research & develop products for the needs of our customers from a vast range of different industries; glass, ceramics, electrical and many more.